Serial Port Spi

Blog Entry Using Serial Peripheral Interface SPI Master and Slave with Atmel AVR Microcontroller June 25, 2009 by rwb, under Microcontroller. Sometimes we need to.

Sometimes we need to extend or add more I/O ports to our microcontroller based project. Because usually we only have a limited I/O port left than the logical choice is to use the serial data transfer method; which usually only requires from one up to four ports for doing the data transfer. Currently there are few types of modern embedded system serial data transfer interface widely supported by most of the chip s manufactures such as I2C read as I square C, SPI Serial Peripheral Interface, 1-Wire One Wire, Controller Area Network CAN, USB Universal Serial Bus and the RS-232 families RS-423, RS-422 and RS-485. The last three interface types is used for long connection between the microcontroller and the devices, up to 1200 meters for the RS-485 specification, while the first three is used for short range connection.

Among these serial data transfer interface types, SPI is considered the fastest synchronous with full duplex serial data transfer interface and can be clocked up to 10 MHz; that is why it is widely used as the interface method to the high speed demand peripheral such as the Microchip Ethernet controller ENC28J60, Multi Media Card MMC Flash Memory, Microchip SPI I/O MCP23S17, Microchip 128K SPI EEPROM 25AA128, ADC, sensors, etc.

In this tutorial we will learn how to utilize the Atmel AVR ATMega168 SPI peripheral to expand the ATMega168 I/O ports and to communicate between two microcontrollers with the SPI peripheral where one microcontroller is configured as a master and other as a slave. The principal we learn here could be applied to other types of microcontroller families.

Serial Peripheral Interface SPI

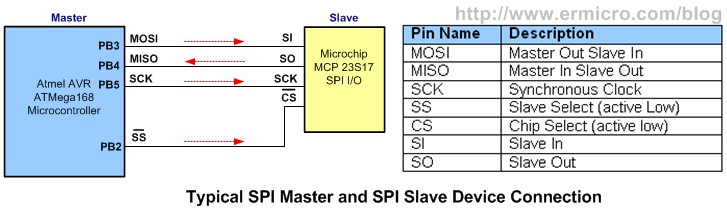

The standard Serial Peripheral Interface uses a minimum of three line ports for communicating with a single SPI device SPI slave, with the chip select pin CS is being always connected to the ground enable. If more the one SPI devices is connected to the same bus, then we need four ports and use the fourth port SS pin on the ATMega168 microcontroller to select the target SPI device before starting to communicate with it.

If more then three SPI slave devices, then it is better to use from three to eight channels decoder chip such as 74HC138 families. Since the SPI protocol uses full duplex synchronous serial data transfer method, it could transfer the data and at the same time receiving the slave data using its internal shift register.

From the SPI master and slave interconnection diagram above you could see that the SPI peripheral use the shift register to transfer and receive the data, for example the master want to transfer 0b10001101 0x8E to the slave and at the same time the slave device also want to transfer the 0b00110010 0 32 data to the master. By activating the CS chip select pin on the slave device, now the slave is ready to receive the data. On the first clock cycle both master and slave shift register will shift their registers content one bit to the left; the SPI slave will receive the first bit from the master on its LSB register while at he same time the SPI master will receive its first data from slave on its LSB register.

Continuously using the same principal for each bit, the complete data transfer between master and slave will be done in 8 clock cycle. By using the highest possible clock allowed such as the Microchip MCP23S17 SPI slave I/O device 10 MHz than the complete data transfer between the microcontroller and this SPI I/O port could be achieve in 0.8 us. As you understand how the SPI principal works, now its time to implement it with the Atmel AVR ATMega168 microcontroller.

The following is the list of hardware and software used in this project:

74HC595, 8-bit shift registers with output latch

Microchip MCP23S17 16-bit SPI I/O Expander

AVRJazz Mega168 board from ermicro which base on the AVR ATmega168 microcontroller board schema.

WinAVR for the GNU s C compiler

Atmel AVR Studio 4 for the coding and debugging environment

STK500 programmer from AVR Studio 4, using the AVRJazz Mega168 board STK500 v2.0 bootloader facility.

Expanding Output Port with 74HC595 8-bit Shift Registers

Because the basic operation of SPI peripheral is a shift register, then we could simply use the 8-bit shift register with output latch to expand the output port. The 16 pins 74HC595 families could be use to serve this purpose.

The 74HC595 device has 8-bit serial-in, parallel-out shift register that feeds directly to the 8-bit D-type storage register. The 8-bit serial-in shift register has its own input clock pin named SCK, while the D-Latch 8-bit registers use pin named RCK for transferring latching the 8-bit shift registers output to D-Latch output registers.

In normal operation according to the truth table above the 74HC595 shift registers clear pin SCLR should be put on logical high and the 8-bit D-Latch buffer output enable pin G should be put on logical low. By feeding the serial input pin SER with AVR ATMega168 master out slave in pin MOSI and connecting the master synchronous clock SCK to the 74HC595 shift registers clock SCK, we could simply use the 74HC595 as the SPI slave device. Optionally we could connect the 74HC595 Q H output pin shift registers MSB bit to the master in slave out pin MISO ; this optional connection will simply returns the previous value of the shift registers to the SPI master register.

Now let s take a look to the C code for sending simple chaser LED display to the 74HC595 output:

// Description : SPI I/O Using 74HC595 8-bit shift registers

// Target : AVRJazz Mega168 Board

// Compiler : AVR-GCC 4.3.0; avr-libc 1.6.2 WinAVR 20080610

// IDE : Atmel AVR Studio 4.14

// Programmer : AVRJazz Mega168 STK500 v2.0 Bootloader

// : AVR Visual Studio 4.14, STK500 programmer

unsigned char SPI_WriteRead unsigned char dataout

// Wait for transmission complete

// Latch the Output using rising pulse to the RCK Pin

_delay_us 1 ; // Hold pulse for 1 micro second

// Return Serial In Value MISO

// Initial the AVR ATMega168 SPI Peripheral

// Set MOSI and SCK as output, others as input

// Enable SPI, Master, set clock rate fck/2 maximum

AVR Serial Peripheral Interface

The principal operation of the SPI is simple but rather then to create our own bit-bang algorithm to send the data, the build in SPI peripheral inside the Atmel AVR ATMega168 microcontroller make the SPI programming become easier as we just passing our data to the SPI data register SPDR and let the AVR ATMega168 SPI peripheral do the job to send and read the data from the SPI slave device. To initialize the SPI peripheral inside the ATMega168 microcontroller we need to enable this device for SPI master and set the master clock frequency using the SPI control register SPCR and SPI status register SPST, for more information please refer to the AVR ATMega168 datasheet.

The first thing before we use the SPI peripheral is to set the SPI port for SPI master operation; MOSI PB3 and SCK PB5 as output port and MISO PB4 is the input port, while the SS can be any port for SPI master operation but on this tutorial we will use the PB2 to select the SPI slave device. The following C code is used to set these SPI ports.

After initializing the ports now we have to enable the SPI by setting the SPE SPI enable bit to logical 1 and selecting the SPI master operation by setting the MSTR bit to logical 1 in the SPCR register. For all other bits we just use its default value logical 0 ; such as the data order DORD bit for first transferring MSB, using the rising clock for the master clock on clock polarity CPOL bit and sampled the data on leading edge clock phase CPHA bit.

Because the 74HC595 shift register can receive up to 30 Mhz clock rate, then I use the fastest clock that can be generated by the ATMega168 microcontroller SPI peripheral which is fsc/2 the AVRJazz Mega168 board using 11.059200 MHz ; therefore the maximum clock generated by the SPI master will be 5.5296 MHz. This frequency can be achieved by setting the SPR1 0 and SPR0 0 in the SPCR register and SPI2X 1 in the SPSR register.

// Enable SPI, Master, set clock rate fck/2 maximum

Sending and reading the data is using the SPI data register SPDT and when the SPI Master-Slave data transfer is completed than SPIF SPI interrupt flag in the SPSR register will be set to logical 1 ; therefore by examining this bit status we could ensure that the transmission between SPI master and slave is completed.

After reading the data from the SPDT register; we have to send the latch clock to the 74HC595 D-Latch register RCK pin to latch the 8-bit shift registers data to its output.

Microchip MCP23S17 SPI I/O Expander

For more advance input and output capability SPI device you could use the Microchip MCP23S17 SPI I/O Expander chip, which provide additional 16-bit I/O for your microcontroller s based project.

With the addressable pins configuration feature A2,A1 and A0, practically you could attach up to 8 of MCP23S17 SPI I/O expander devices which gives you 128 I/O ports using just four of your AVR ATMega168 microcontroller s ports MOSI, MISO, SCK and SS.

All the MCP23S17 16-bit general purpose I/O GPIO ports can be configured both as input or output by setting the MCP23S17 IODIRA and IODIRB I/O direction register. Each of the MCP23S17 general I/O pins could be configured to generate interrupt when the ports pin changes its state for more information please refers to Microchip MCP23S17 datasheet.

For the purpose of this tutorial we will use the Microchip MCP23S17 just as the ordinary input and output expander for the AVR ATMega168 microcontroller.

The MCP23S17 is configured to use address 0 00 address pins A0,A1 and A2 are connected to the ground and the push button switch connected to GPB0 port will be use as the toggle button to start and stop the chaser LED display attached to the GPA0 to GPA7 ports. The following is the C code to achieve these tasks.

// Description : SPI I/O Using Microchip MCP23S17 16-Bit I/O Expander

define SPI_SLAVE_ADDR 0x00 // A2 0,A1 0,A0 0

// MCP23S17 Registers Definition for BANK 0 default

// Define MCP23S17 Slave Emulation Mode:

// Only works on real Microchip MCP23S17 SPI I/O

// 1 - ATMega168 SPI Slave MCP23S17 Emulation :

// Both works on real MCP23S17 and ATMega168 Slave Mode

// ATMega168 Crystal Frequency: 11059200 Hz

void SPI_Write unsigned char addr,unsigned char data

// Start MCP23S17 OpCode transmission

SPDR SPI_SLAVE_ID SPI_SLAVE_ADDR

// Start MCP23S17 Register Address transmission

unsigned char SPI_Read unsigned char addr

// Start MCP23S17 Address transmission

// Send Dummy transmission for reading the data

unsigned char cnt,togbutton,inp;

// Initial ATMega168 ADC Peripheral for User s Trimpot Input on PC0

// Disable digital input on ADC0 PC0

ADMUX 0x00; // Select Channel 0 PC0

// Set MOSI PB3, SCK PB5 and PB2 SS as output, others as input

// Enable SPI, Master, set clock rate fck/64

// Enable SPI, Master, set clock rate fck/2

// Initial the MCP23S17 SPI I/O Expander

SPI_Write IOCONA,0x28 ; // I/O Control Register: BANK 0, SEQOP 1, HAEN 1 Enable Addressing

SPI_Write IODIRA,0x00 ; // GPIOA As Output

SPI_Write IODIRB,0xFF ; // GPIOB As Input

SPI_Write GPPUB,0xFF ; // Enable Pull-up Resistor on GPIOB

SPI_Write GPIOA,0x00 ; // Reset Output on GPIOA

inp SPI_Read GPIOB ; // Read from GPIOB

if inp 0xFE // Button is pressed

inp SPI_Read GPIOB ; // Read from GPIOB, for simple debounce

SPI_Write GPIOA,0x00 ; // Write to MCP23S17 GPIOA

// Start conversion by setting ADSC on ADCSRA Register

// wait until convertion complete ADSC 0 - Complete

SPI_Write GPIOA,pattern cnt ; // Write to MCP23S17 GPIOA

PORTD pattern cnt ; // Write to PORTD

Unlike the 74HC595 8-bit shift register above, writing and reading to and from the MCP23S17 SPI slave must be done in three SPI master writing operation cycles. First the SPI master has to send the MCP23S17 SPI slave ID with its physical address set by A2, A1 and A0 pins and the read or write instruction to the MCP23S17. Secondly the SPI master has to tell MCP23S17 which one of the MCP23S17 control registers address we want to use, and the last one we send or read the actual data.

From the MCP23S17 SPI addressing diagram above you could see that at least we need to perform three SPI master writing to send or read the data to or from the MCP23S17 SPI slave I/O expander. Using the same principal we ve learned from the 74HC595 to send the data we simply supply the correct data to the ATMega168 microcontroller SPDR register while keep the SS PB2 pin low to enable the MCP23S17 SPI slave device. After all data has been sent or read then we raise logical 1 the SS PB2 pin to deactivate the SPI slave device.

The SPI_Write and the SPI_Read function are used to do the write and read to and from the MCP23S17 SPI slave. As you ve seen from the SPI_Read function code above because the SPI slave could not initiate its own data transfer therefore the SPI master has to start the data transfer by sending the dummy data 0 00 to the SPI slave in order to read the SPI slave data.

The MCP23S17 SPI I/O expander has two general I/O ports named GPIOA and GPIOB. The default power-up condition of MCP23S17 is all I/O ports configured as an input port. By changing each of the I/O direction registers IODIRA and IODIRB we could change this port behavior; this pretty much the same as we set the data direction register on the ATMega168 microcontroller I/O ports. The following code shows how to initialize the MCP23S17 SPI I/O expander.

SPI_Write IOCONA,0x28 ; // I/O Control Register: BANK 0, SEQOP 1, HAEN 1 Enable Addressing

By assigning the IODIRA with 0 00 and IODIRB with 0xFF, we tell MCP23S17 to assign its GPIOA ports as output and GPIOB as input. Remember this setup is different compare to the ATMega168 microcontroller data direction register, which use 0xFF for output and 0 00 for input. To make sure all the GPIOB input ports are on known state all ports high, we activate the MCP23S17 pull-up resistors by assigning 0xFF to the GPPUB register.

To enable the MCP23S17 addressing mode, we have to enable logical 1 the HAEN bit on the IOCONA register. The IOCONA and IOCONB registers actually shared the same bit; therefore you could change either the IOCONA or IOCONB.

Assigning 0 28 to the IOCON register means we used the BANK 0 addressing mode, disable the sequential address increment and we enable the address bit control on A2, A1 and A0 pins of MCP23S17 current implementation A2 0, A1 0, and A0 0.

After configure the MCP23S17 registers, we entering the infinite loop which simple read the MCP23S17 GPIOB input port and if the switch is pressed then start sending the LED display patterns to the MCP23S17 GPIOA output port and to the ATMega168 PORTD which is also configured as the output port.

The LED display delay is controlled by the user s trimport on the AVRJazz Mega168 board which connected to the ADC channel 0 PC0, for further information about using the ATMega168 microcontroller ADC peripheral please refer to my previous posted blog Analog to Digital Converter AVR C Programming.

AVR ATMega168 microcontroller as the SPI Slave Device

In this last AVR SPI tutorial we will transform a second AVR ATMega168 to the SPI slave I/O device; in order not to change the SPI master demo program shown on the MCP23S17 section above, I decided to emulate some functions of the Microchip MCP23S17 SPI I/O expander using the Atmel AVR ATMega168 microcontroller and at the same time it will give us a good example of how to program the AVR ATMega168 microcontroller as the SPI slave device.

The SPI slave device practically is a passive device which means that the SPI device could not initiate the data transfer to the SPI Master. Its rely only on the SPI Master to first transfer its data then at the same time the SPI slave could transfer its own data to the SPI master. The C code bellows show how the Atmel AVR ATMega168 microcontroller being transformed to the Microchip MCP23S17 SPI I/O expander:

// Description : SPI I/O Using ATMega168 as the SPI Slave device

// Partial Emulation of MCP23S17 SPI I/O Expander

// PORTD - GPIOA, PORTB.PB0 - GPIOB.GPB0

// MCP23S17 Emulation Read Write OpCode

unsigned char datain,dataout,slavereg;

// MCP23S17 Registers Emulation Variables

// Initial the AVR ATMega168 SPI Slave Peripheral

// Set MISO PB4 as output, others as input

state 0; // State: 0-ID and Address, 1-Register, 2-Data

// Reset All the MCP23S17 Slave Emulation Registers

datain SPI_WriteRead dataout ;

// Check for MCP23S17 Slave Emulation OpCode

// For MCP23S17 implemented register, change the state

if datain IODIRA datain IODIRB datain IOCONA datain GPPUA

datain GPPUB datain GPIOA datain GPIOB

// For Read Condition then prepare for returning value on the next master cycle

// Complement Data, ATMega168 DDR use 1 for Output Data Direction

iodirb datain 0x01; // Just put it on variable

// Only for input PB0, ignore output and other ports

iocona datain; // Just put it on variable

gppua datain; // Just put it on variable

gppub datain; // Just put it on variable

PORTD datain; // Passing data to the real port

gpiob datain; // Passing data to the emulation register

The ATMega168 microcontroller SPI slave initiation can be done by simply enabling the MISO port PB4 as the output port and enabling the SPI peripheral bit SPE logical 1 in the SPCR register. By polling the SPDR register using the SPI_WriteRead function we could examine the data send by the SPI Master using the state condition algorithm to emulate the Microchip MCP23S17 SPI I/O expander partial functionality as shown inside the infinite loop code.

The first state cycle checks if the SPI master is sending the MCP23S17 ID 0100 and the address currently implemented as 000 and examines if this is READ 1 or WRITE 0 operation code.

The second state cycle check for implemented MCP23S17 control registers IODIRA, IODIRB,IOCONA,GPPUA,GPPUB,GPIOA, and GPIOB and at the same time prepares the data to be sent to the SPI Master on the next SPI master cycle if this is the READ operation

The third state cycle final state send the SPI slave data to the SPI master, executes the WRITE operation using the last data sent by the SPI master to the MCP23S17 emulated registers and resets the state cycle variables for the next new SPI master command.

If you notice in the SPI master code above MCP23S17 section, I include the define MCP23S17_EMULATION 1 compiler directive; which give slightly different code when it turn off define MCP23S17_EMULATION 0.

When you turn off this compiler directive the SPI master clock setting will use the fastest possible clock fsck/2 5.5296 MHz, but this clock rate will not work on the ATMega168 SPI slave, it only work on real Microchip MCP23S17 SPI I/O expander; therefore for the ATMega168 SPI slave we use the fck/64 172.800 KHz with 11.059200 MHz crystal clock on the AVRJazz Mega168 board.

Now you could enjoy the following video showing all the experiments we ve done in this tutorial:

Currently the Serial Peripheral Interface SPI is lack of the standard specification, its also called de facto standard, rather than one standard protocol specification agreed by the international committee. This lack of the standardization lead to the wide SPI protocol option implemented by various manufactures; for example as shown on the SPI data transfer to the 74HC595 8-bit shift register tutorial above, we use different chip select logical signal to latch the 74HC595 D-Latch register compared to the real SPI slave I/O device such as Microchip MCP23S17.

Nevertheless the SPI is out there; it s still considered as one of the best and fastest embedded systems serial data transfers available today and it s supported by most of the IC integrated circuit leading manufactures.

You must be logged in to post a comment.

AVRJazz Mega168/328 Learning and Development Board

November 11, 2008 by admin, under Development Board News.

The AVRJazz Mega168 board from ermicro is designed to be used both as the AVR microcontroller learning and development board. The AVR Jazz Mega168 board is stand alone microcontroller module equipped with the latest Atmel high performance low power technology AVR ATMega168 or ATMega328 microcontroller that can be used for wide range of applications including embedded controller, remote data logger, robotics and much more.

The AVRJazz Mega168 board features

High performance low power Atmel ATMega168 microcontroller with 16 Kbytes Self-Programmable Flash 2 Kbytes used for bootloader program, 512 Kbytes EEPROM and 1Kbytes Internal SRAM. Peripherals include: two 8 bit and one 16 Bit Timers/Counter, six PWM channels, six-channels 10 bit ADC, Analog Comparator, USART, Master/Slave SPI and I2C

Eight 3mm blue LED attached to the Port D through 74HCT240 buffer

One user potentiometer for analog input

Adjustable ADC Voltage reference

Buzzer for playing sound connected to one of the AVR 16bit PWM channel

High speed instruction throughput using 11 Mhz Crystal

RS232 Level converter for communicating with other equipment such as PC

LM35DZ Precision Centigrade Temperature Sensor for measuring temperature

Microchip 16 Kbytes I2C EEPROM using 24AA128 for data storage

Fully supported by Atmel AVR Studio 4 and AVR-GCC

Compatible with Arduino Integrated Development Environment which give you more flexible programming environment Windows or Linux and lots of program examples from the Arduino forum

STK500 v2.0 compatible preprogrammed boot loader, no external hardware is required to re programmed the AVRJazz Mega168 board

ISP Port to re programmed the AVRJazz Mega168 board with Atmel AVR ISP programmer such as Atmel AVRISP mkII

The AVRJazz Mega168 board microcontroller socket is pin compatible with Atmel 8-bit 28 pins microcontrollers such as ATMega44 4K, ATMega8 8K, ATMega88 8K, ATMega168 16K and ATMega328 32K.

Example project using AVRJazz Mega168 board could be found on ermicroblog

The AVRJazz Mega168 board demo program source code is include in the CDROM; this program demonstrate the capability of the AVRJazz Mega168 board such as accessing the I2C 24AA128 EEPROM, reading the LM35DZ centigrade temperature sensor, using the RS232 port, using the user switch, using the user analog input trimport and running the eight 3mm blue LED.

Running the AVRJazz Mega168 demonstration program

The AVRJazz Mega168 Board comes preprogrammed with a demonstration program. To use this program, connect the AVRJazz to the battery power that come with the board. The demo program will display the chasing light on the eight blue LED mode 0. Rotate the user trimport, labeled R12, and the chasing led speed will change in different rate. Press the user switch, labeled S2, and now the board will display the room temperature through the RS232 port mode 1, press the S2 switch again, the board will play a sound mode 2 and automatically back to mode 0.

The temperature could be monitor with Windows Hyperterminal or puTTY program on your computer. Connect the RS232 cable come with the board directly to your computer COM and start the Hyperterminal or puTTY using this following setting: 19200 baud rate, 8 bit Data, Parity: None and 1 Stop Bit.

Programming the AVRJazz Mega168 Board

AVRJazz Mega168 board comes with the preprogrammed bootloader program that utilized the Atmel ATMega168 microcontroller self programming feature; combined with the RS232 make it possible to reprogram the AVRJazz board without using any external hardware. The preprogrammed bootloader use the latest STK500 ver 2.0 protocol for faster and more efficient data downloading. The STK500 downloader which include in AVR Studio 4 is use as the PC front end to download the HEX data through RS232 interface connected to the AVRJazz Mega168 board.

Down loading AVRJazz Mega168 board Sample Program

Run the AVR Studio 4 assuming the WinAVR program is already installed on your computer and load the following sample C program ScanningEye.c on the project or you could use your own program:

// File Name : ScanningEye.c

// Description : Learning Lessons: Shifting the Output

// Target : AVRJazz Mega168 Board

// Compiler : AVR-GCC 4.3.0; avr-libc 1.6.2 WinAVR 20090313

// IDE : Atmel AVR Studio 4.17

// : AVR Visual Studio 4.17, STK500 programmer

DDRD 0xFF; // Set PORTD as Output

PORTD 0xFF; // Set All PORTD to High

chEye 0x01; // Initial Eye Variables with 0000 0001

for ;; // Loop Forever

_delay_ms 100 ; // Delay 100 millisecond

return 0; // Standard Return Code

2. Set the AVRJazz Mega168 board into the programming mode by pressing the Reset Button S1 followed by the User Switch Button S2 at the same time, two indicator LED will lid active UART transmission and the board is ready for accepting command through the RS232 port If you don t have RS232 port on your PC, you could use the USB to RS232 adapter.

3. Before compile and build the program, check the compiler configuration option menu Project - Configuration Options as follow:

Make sure the device selected is atmega168 atmega328P for the AVRJazz Mega328 board and the frequency is set to 11059200 Hz. Leave the other setting to its default.

4. Press F7 or through Build - Build menu, if no error occurs than you could simply continue download the HEX generated file compiled file to the board.

5. To download the HEX file to the AVRJazz Mega168 board, select Program AVR from Tools menu end choose the Connect this will open the AVR programmer selection screen and Select the STK500 or AVRISP Platform and Auto for the Port then click the Connect button.

Select the HEX File to be loaded usually is in the default directory for WinAVR C program then click the Program button. After finish; the programmer will show the result as follow:

Getting isp parameter.. SD 0x00. . OKOK

Setting mode and device parameters.. OK.

Entering programming mode.. OK.

FLASH contents is equal to file.. OK

Leaving programming mode.. OK.

6. Close the AVR programmer program and press the reset button on the AVRJazz Mega168 board to run the loaded program.

Using AVRJazz Mega168 Board with Arduino IDE

AVRJazz Mega168 could be easily programmed with the Arduino IDE Integrated Development Environment, before programming this board in the Arduino IDE; you have to change these following:

c: Documents and Settings Application Data Arduino preferences.txt

Open the preference.txt files with your text editor e.g. notepad.exe, this file automatically created when you run the Aurdino IDE for the first time; update the default Arduino upload method from bootloader to avrjazz search the upload.using bootloader line using your text editor search or find command

Then edit the Arduino board programmer definition which located on hardware programmers.txt and add these AVRJazz Mega168 board programmer definition lines as follow:

parallel.name Parallel Programmer

Now start your Arduino IDE and load the Arduino blink example program menu File - Sketchbook - Examples - Digital - Blink as follow:

Now set the Arduino board by selecting from menu Tools - Board - Arduino NG or older w/ ATMega168 and then you could start compiling the Arduino blink program menu Sketch - Verlfy/Compile and upload the code File - Upload to I/O Board to the AVRJazz Mega168 board; the board should be in the programming mode to be able to receive the data from Arduino IDE.

After upload the code, then press the reset button on the AVRJazz Mega168 board to run the new loaded program; now the LED connected to the ATMega168 PORTD PD7 digital I/O 7 on Arduino environment will blink continuously every 1 second.

The AVRJazz board series also come with powerful Atmel AVR Mega328 Microcontroller which has the same features as the AVRJazz Mega168 microcontroller, only this microcontroller has twice the memory compare to the AVR Mega168 microcontroller.

When uisng AVRJazz Mega328 with the Arduino environment make sure you choose the Arduino w/ATmega328 setting Tools - Board - Ardino w/ATmega328.

With twice the memory as the AVRJazz Mega168 board, the AVRJazz Mega328 learning and development board will give more room to enhance the board usage especially when we combine this board with enormous external devices supported by the AVR Mega328 microcontroller such as I2C I squared C and SPI devices.

AVRJazz Mega168 Specification:

1. Atmel ATMega168 Microcontroller running on 11.059200 Mhz

2. Microchip 16 Kbytes I2C EEPROM 24AA128

3. LM35DZ Centigrade precision temperature sensor

4. LED s output driver 74HC240 buffer

9. One User Analog Input Trimport

11. Adjustable ADC reference voltage input

AVRJazz Mega168 Board Power Requirement:

Well regulated power supply: 3 Volt – 5 Volt

Accessories include with the AVRJazz Mega168 Board:

1. One AVRJazz Mega168 RS232 Cable

2. One 3xAA 1.5 Volt Battery Holder battery not include

3. 4 x Metal Standoffs for supporting the AVRJazz Mega168 Board

4. 1 CD User Guide and Sample Program

Get the AVRJazz Mega168/328 Board Now.

SPI bus: single master and single slave

The Serial Peripheral Interface or SPI bus is a synchronous serial data link, a de facto standard, named by Motorola, that operates in full duplex mode. It is used for short distance, single master communication, for example in embedded systems, sensors, and SD cards.

Devices communicate in master/slave mode where the master device initiates the data frame. Multiple slave devices are allowed with individual slave select lines. Sometimes SPI is called a four-wire serial bus, contrasting with three-, two-, and one-wire serial buses. SPI is often referred to as SSI Synchronous Serial Interface.

2.1.1 Clock polarity and phase

2.2 Independent slave SPI configuration

2.3 Daisy chain SPI configuration

2.6 Example of bit-banging the SPI master protocol

7.1 Intelligent SPI controllers

7.7 Intel Enhanced Serial Peripheral Interface Bus

The SPI bus specifies four logic signals:

SCLK : Serial Clock output from master.

MOSI : Master Output, Slave Input output from master.

MISO : Master Input, Slave Output output from slave.

SS : Slave Select active low, output from master.

Alternative naming conventions are also widely used, and SPI port pin names for particular IC products may differ from those depicted in these illustrations:

MOSI : SIMO, SDO for master devices, SDI for slave devices, DO, DOUT, SI, MTSR.

MISO : SOMI, SDO for slave devices , SDI for master devices, DI, DIN, SO, MRST.

SS : nCS, CS, CSB, CSN, nSS, STE, SYNC.

The MOSI/MISO convention requires that, on devices using the alternate names, SDI on the master be connected to SDO on the slave, and vice versa. Chip select polarity is rarely active high, although some notations such as SS or CS instead of nSS or nCS suggest otherwise. Slave select is used instead of an addressing concept.

The SPI bus can operate with a single master device and with one or more slave devices.

If a single slave device is used, the SS pin may be fixed to logic low if the slave permits it. Some slaves require a falling edge of the chip select signal to initiate an action, an example is the Maxim MAX1242 ADC, which starts conversion on a high low transition. With multiple slave devices, an independent SS signal is required from the master for each slave device.

Most slave devices have tri-state outputs so their MISO signal becomes high impedance logically disconnected when the device is not selected. Devices without tri-state outputs cannot share SPI bus segments with other devices; only one such slave could talk to the master, and only its chip select could be activated.

A typical hardware setup using two shift registers to form an inter-chip circular buffer

To begin a communication, the bus master first configures the clock, using a frequency less than or equal to the maximum frequency the slave device supports. Such frequencies are typically up to a few MHz.

The master then transmits the logic 0 for the desired chip over the chip select line. A logic 0 is transmitted because the chip select line is active low, meaning its off state is a logic 1; on is asserted with a logic 0. If a waiting period is required such as for analog-to-digital conversion, then the master must wait for at least that period of time before starting to issue clock cycles.

During each SPI clock cycle, a full duplex data transmission occurs:

the master sends a bit on the MOSI line; the slave reads it from that same line

the slave sends a bit on the MISO line; the master reads it from that same line

Not all transmissions require all four of these operations to be meaningful, but they do happen.

Transmissions normally involve two shift registers of some given word size, such as eight bits, one in the master and one in the slave; they are connected in a ring. Data is usually shifted out with the most significant bit first, while shifting a new least significant bit into the same register. After that register has been shifted out, the master and slave have exchanged register values. Then each device takes that value and does something with it, such as writing it to memory. If there is more data to exchange, the shift registers are loaded with new data 1 and the process repeats.

Transmissions may involve any number of clock cycles. When there is no more data to be transmitted, the master stops toggling its clock. Normally, it then deselects the slave.

Transmissions often consist of 8-bit words. A master can initiate multiple such transmissions if it wishes/needs. However, other word sizes are also common, such as 16-bit words for touchscreen controllers or audio codecs, like the TSC2101 from Texas Instruments; or 12-bit words for many digital-to-analog or analog-to-digital converters.

Every slave on the bus that has not been activated using its chip select line must disregard the input clock and MOSI signals, and must not drive MISO. The master must select only one slave at a time.

A timing diagram showing clock polarity and phase. The red vertical line represents CPHA 0 and the blue vertical line represents CPHA 1

In addition to setting the clock frequency, the master must also configure the clock polarity and phase with respect to the data. Freescale s SPI Block Guide 2 names these two options as CPOL and CPHA respectively, and most vendors have adopted that convention.

The timing diagram is shown to the right. The timing is further described below and applies to both the master and the slave device.

At CPOL 0 the base value of the clock is zero

For CPHA 0, data are captured on the clock s rising edge low high transition and data is propagated on a falling edge high low clock transition.

For CPHA 1, data are captured on the clock s falling edge and data is propagated on a rising edge.

At CPOL 1 the base value of the clock is one inversion of CPOL 0

For CPHA 0, data are captured on clock s falling edge and data is propagated on a rising edge.

For CPHA 1, data are captured on clock s rising edge and data is propagated on a falling edge.

That is, CPHA 0 means sample on the leading first clock edge, while CPHA 1 means sample on the trailing second clock edge, regardless of whether that clock edge is rising or falling. Note that with CPHA 0, the data must be stable for a half cycle before the first clock cycle.

The MOSI and MISO signals are usually stable at their reception points for the half cycle until the next clock transition. SPI master and slave devices may well sample data at different points in that half cycle.

This adds more flexibility to the communication channel between the master and slave.

Some products use different naming conventions. For example, the TI MSP430 uses the name UCCKPL instead of CPOL, and its UCCKPH is the inverse of CPHA. When connecting two chips together, the clock phase initialization values must be examined to be sure of using the right settings.

The combinations of polarity and phases are often referred to as modes which are commonly numbered according to the following convention, with CPOL as the high order bit and CPHA as the low order bit:

For Microchip PIC / ATMEL AVR / ARM-based microcontrollers:

Another commonly used notation represents the mode as a CPOL, CPHA tuple; e.g., the value 0, 1 would indicate CPOL 0 and CPHA 1

Refer to Section Serial Peripheral Interface SPI in your Micro datasheet controller for more information.

Independent slave SPI configuration edit

Typical SPI bus: master and three independent slaves

In the independent slave configuration, there is an independent chip select line for each slave. This is the way SPI is normally used. Since the MISO pins of the slaves are connected together, they are required to be tri-state pins high, low or high-impedance.

Daisy chain SPI configuration edit

Daisy-chained SPI bus: master and cooperative slaves

Some products with SPI bus are designed to be capable of being connected in a daisy chain configuration, the first slave output being connected to the second slave input, etc. The SPI port of each slave is designed to send out during the second group of clock pulses an exact copy of what it received during the first group of clock pulses. The whole chain acts as an SPI communication shift register; daisy chaining is often done with shift registers to provide a bank of inputs or outputs through SPI. Such a feature only requires a single SS line from the master, rather than a separate SS line for each slave. 3

Applications discussed later that require a daisy chain configuration include SGPIO and JTAG

Some slave devices are designed to ignore any SPI communications in which the number of clock pulses is greater than specified. Others do not care, ignoring extra inputs and continuing to shift the same output bit. It is common for different devices to use SPI communications with different lengths, as, for example, when SPI is used to access the scan chain of a digital IC by issuing a command word of one size perhaps 32 bits and then getting a response of a different size perhaps 153 bits, one for each pin in that scan chain.

SPI devices sometimes use another signal line to send an interrupt signal to a host CPU. Examples include pen-down interrupts from touchscreen sensors, thermal limit alerts from temperature sensors, alarms issued by real time clock chips, SDIO, and headset jack insertions from the sound codec in a cell phone. Interrupts are not covered by the SPI standard; their usage is neither forbidden nor specified by the standard.

Example of bit-banging the SPI master protocol edit

Below is an example of bit-banging the SPI protocol as an SPI master with CPOL 0, CPHA 0, and eight bits per transfer. The example is written in the C programming language. Because this is CPOL 0 the clock must be pulled low before the chip select is activated. The chip select line must be activated, which normally means being toggled low, for the peripheral before the start of the transfer, and then deactivated afterwards. Most peripherals allow or require several transfers while the select line is low; this routine might be called several times before deselecting the chip.

Simultaneously transmit and receive a byte on the SPI.

Polarity and phase are assumed to be both 0, i.e.:

- input data is captured on rising edge of SCLK.

- output data is propagated on falling edge of SCLK.

uint8_t SPI_transfer_byte uint8_t byte_out

/ Shift-out a bit to the MOSI line /

write_MOSI byte_out bit . HIGH : LOW ;

/ Delay for at least the peer s setup time /

/ Shift-in a bit from the MISO line /

/ Delay for at least the peer s hold time /

Full duplex communication in the default version of this protocol.

Higher throughput than I C or SMBus

Complete protocol flexibility for the bits transferred

Arbitrary choice of message size, content, and purpose

Extremely simple hardware interfacing

Typically lower power requirements than I C or SMBus due to less circuitry including pull up resistors

No arbitration or associated failure modes

Slaves use the master s clock, and do not need precision oscillators

Slaves do not need a unique address unlike I C or GPIB or SCSI

Uses only four pins on IC packages, and wires in board layouts or connectors, much fewer than parallel interfaces

At most one unique bus signal per device chip select ; all others are shared

Signals are unidirectional allowing for easy Galvanic isolation

Not limited to any maximum clock speed, enabling potentially high throughput

Requires more pins on IC packages than I C, even in the three-wire variant

No in-band addressing; out-of-band chip select signals are required on shared buses

No hardware flow control by the slave but the master can delay the next clock edge to slow the transfer rate

No hardware slave acknowledgment the master could be transmitting to nowhere and not know it

Supports only one master device

No error-checking protocol is defined

Without a formal standard, validating conformance is not possible

Only handles short distances compared to RS-232, RS-485, or CAN-bus

Many existing variations, making it difficult to find development tools like host adapters that support those variations

SPI does not support hot plugging dynamically adding nodes.

Interrupts must either be implemented with out-of-band signals or be faked by using periodic polling similarly to USB 1.1 and 2.0

Some variants like Multi I/O SPI and three-wire serial buses defined below are half-duplex.

The board real estate savings compared to a parallel I/O bus are significant, and have earned SPI a solid role in embedded systems. That is true for most system-on-a-chip processors, both with higher end 32-bit processors such as those using ARM, MIPS, or PowerPC and with other microcontrollers such as the AVR, PIC, and MSP430. These chips usually include SPI controllers capable of running in either master or slave mode. In-system programmable AVR controllers including blank ones can be programmed using an SPI interface. 4

Chip or FPGA based designs sometimes use SPI to communicate between internal components; on-chip real estate can be as costly as its on-board cousin.

The full-duplex capability makes SPI very simple and efficient for single master/single slave applications. Some devices use the full-duplex mode to implement an efficient, swift data stream for applications such as digital audio, digital signal processing, or telecommunications channels, but most off-the-shelf chips stick to half-duplex request/response protocols.

SPI is used to talk to a variety of peripherals, such as

Sensors: temperature, pressure, ADC, touchscreens, video game controllers

Control devices: audio codecs, digital potentiometers, DAC

Camera lenses: Canon EF lens mount

Communications: Ethernet, USB, USART, CAN, IEEE 802.15.4, IEEE 802.11, handheld video games

LCD, sometimes even for managing image data

Any MMC or SD card including SDIO variant

For high performance systems, FPGAs sometimes use SPI to interface as a slave to a host, as a master to sensors, or for flash memory used to bootstrap if they are SRAM-based.

JTAG is essentially an application stack for a three-wire SPI flavor, using different signal names: citation needed TCK not SCK, TDI not MOSI, TDO not MISO. It defines a state machine driven by a TMS signal instead of a chip select line, protocol messages, a core command set, the ability to daisy-chain devices in a scan chain, and how vendors define new commands. The devices in a scan chain are initially treated as a single device, and transitions on TMS update their state machines; once the individual devices are identified, commands may be issued that affect only one device in that scan chain. Different vendors use different JTAG connectors. Bit strings used in JTAG are often long and not multiples of 8 bit words; for example, a boundary scan reports signal state on each of several hundred pins.

SGPIO is essentially another incompatible application stack for SPI designed for particular backplane management activities. citation needed SGPIO uses 3-bit messages.

The SPI bus is a de facto standard. However, the lack of a formal standard is reflected in a wide variety of protocol options. Different word sizes are common. Every device defines its own protocol, including whether or not it supports commands at all. Some devices are transmit-only; others are receive-only. Chip selects are sometimes active-high rather than active-low. Some protocols send the least significant bit first.

Some devices even have minor variances from the CPOL/CPHA modes described above. Sending data from slave to master may use the opposite clock edge as master to slave. Devices often require extra clock idle time before the first clock or after the last one, or between a command and its response. Some devices have two clocks, one to read data, and another to transmit it into the device. Many of the read clocks run from the chip select line.

Some devices require an additional flow control signal from slave to master, indicating when data are ready. This leads to a 5-wire protocol instead of the usual 4. Such a ready or enable signal is often active-low, and needs to be enabled at key points such as after commands or between words. Without such a signal, data transfer rates may need to be slowed down significantly, or protocols may need to have dummy bytes inserted, to accommodate the worst case for the slave response time. Examples include initiating an ADC conversion, addressing the right page of flash memory, and processing enough of a command that device firmware can load the first word of the response. Many SPI masters do not support that signal directly, and instead rely on fixed delays.

Many SPI chips only support messages that are multiples of 8 bits. Such chips can not interoperate with the JTAG or SGPIO protocols, or any other protocol that requires messages that are not multiples of 8 bits.

There are also hardware-level differences. Some chips combine MOSI and MISO into a single data line SI/SO ; this is sometimes called three-wire signaling in contrast to normal four-wire SPI. Another variation of SPI removes the chip select line, managing protocol state machine entry/exit using other methods. Anyone needing an external connector for SPI defines their own: UEXT, JTAG connector, Secure Digital card socket, etc. Signal levels depend entirely on the chips involved.

When developing or troubleshooting systems using SPI, visibility at the level of hardware signals can be important.

There are a number of USB hardware solutions to provide computers, running Linux, Mac, or Windows, SPI master and/or slave capabilities. Many of them also provide scripting and/or programming capabilities Visual Basic, C/C, VHDL etc..

An SPI host adapter lets the user play the role of a master on an SPI bus directly from PC. They are used for embedded systems, chips FPGA/ASIC/SoC and peripheral testing, programming and debugging.

The key parameters of SPI adapters are: the maximum supported frequency for the serial interface, command-to-command latency and the maximum length for SPI commands. It is possible to find SPI adapters on the market today that support up to 100 MHz serial interfaces, with virtually unlimited access length.

SPI protocol being a de facto standard, some SPI host adapters also have the ability of supporting other protocols beyond the traditional 4-wires SPI for example, support of quad-SPI protocol or other custom serial protocol that derive from SPI 5.

Examples of SPI adapters manufacturers in alphabetical order :

SPI protocol analyzers are tools which sample an SPI bus and decode the electrical signals to provide a higher-level view of the data being transmitted on a specific bus.

Every major oscilloscope vendor offers oscilloscope-based triggering and protocol decoding for SPI. Most support 2-, 3-, and 4-wire SPI. The triggering and decoding capability is typically offered as an optional extra. SPI signals can be accessed via analog oscilloscope channels or with digital MSO channels. 6

When developing and/or troubleshooting the SPI bus, examination of hardware signals can be very important. Logic analyzers are tools which collect, analyze, decode, store signals so people can view the high-speed waveforms at their leisure. Logic analyzers display time-stamps of each signal level change, which can help find protocol problems. Most logic analyzers have the capability to decode bus signals into high-level protocol data and show ASCII data.

Intelligent SPI controllers edit

The queued serial peripheral interface QSPI is one type of SPI controller, not another bus type. It uses a data queue with programmable queue pointers allowing some data transfers without CPU intervention. 7 It also has a wrap-around mode allowing continuous transfers to and from the queue with no CPU intervention. Consequently, the peripherals appear to the CPU as memory-mapped parallel devices. This feature is useful in applications such as control of an A/D converter. Other programmable features in QSPI are chip selects and transfer length/delay.

SPI controllers from different vendors support different feature sets; such DMA queues are not uncommon, although they may be associated with separate DMA engines rather than the SPI controller itself, such as used by multichannel buffered serial port MCBSP. 8 Most SPI master controllers integrate support for up to four chip selects, 9 although some require chip selects to be managed separately through GPIO lines.

Microwire, 10 often spelled μWire, is essentially a predecessor of SPI and a trademark of National Semiconductor. It s a strict subset of SPI: half-duplex, and using SPI mode 0. Microwire chips tend to need slower clock rates than newer SPI versions; perhaps 2 MHz vs. 20 MHz. Some Microwire chips also support a three-wire mode, which fits neatly with the restriction to half-duplex.

Microwire/Plus 11 is an enhancement of Microwire and features full-duplex communication and support for SPI modes 0 and 1. There was no specified improvement in serial clock speed.

As mentioned, one variant of SPI uses single bidirectional data line slave out/slave in, called SISO instead of two unidirectional ones MOSI and MISO. This variant is restricted to a half duplex mode. It tends to be used for lower performance parts, such as small EEPROMs used only during system startup and certain sensors, and Microwire. Few SPI master controllers support this mode; although it can often be easily bit-banged in software.

As opposed to three-wire serial buses, multi I/O SPI uses multiple parallel data lines e.g., IO0 to IO3 to increase throughput. Dual I/O SPI using two data lines has comparable throughput to fast single I/O MISO/MOSI. Quad I/O SPI using four data lines has approximately double the throughput. 12 Multi I/O SPI devices tend to be half duplex similar to three-wire devices to avoid adding too many pins. These serial memory devices combine the advantage of more speed with reduced pin count as compared to parallel memory.

Typical mSPI bus: master and three independent slaves

mSPI mini-SPI is a modification initially developed by Dimitech for their programmable modules. Unlike the standard SPI, four signal lines are always required no matter of the number of slave devices. Its overall simplicity allows the use of standard SPI controllers with a very thin software layer.

All slave devices share the same SS Slave Select; active low line, along with the other three SPI signals: SCLK, MOSI and MISO. Additionally all slave devices normally have their MISO line disconnected from the bus in a high impedance state. As in the standard SPI, begin of transmission is marked by the activation of the SS line low and the end is marked by its return to high. mSPI requires the bus master to issue a slave address typically 8 bits as mandatory first word in every transmission. Since all slave devices share the same SS line, the address word will be received by all of them at the same time. From that point further, only the device with the specified address will connect its MISO line to the bus and start communicating, while all other slave devices will ignore any data and wait for a new start of transmission and address. mSPI solves some of the basic disadvantages of the standard SPI at the expense of a slight decrease in the overall communication speed due to the initial addressing.

Intel Enhanced Serial Peripheral Interface Bus edit

Intel is currently developing a successor to its Low Pin Count LPC bus that it calls the Enhanced Serial Peripheral Interface Bus, or eSPI for short. Intel aims to allow the reduction in the number of pins required on motherboards compared to systems using LPC, have more available throughput than LPC, reduce the working voltage to 1.8 volts to facilitate smaller chip manufacturing processes, allow eSPI peripherals to share SPI flash devices with the host the LPC bus did not allow firmware hubs to be used by LPC peripherals, tunnel previous out-of-band pins through the eSPI bus, and allow system designers to trade off cost and performance. 13

The eSPI bus can either be shared with SPI devices to save pins or be separate from the SPI bus to allow more performance, especially when eSPI devices need to use SPI flash devices. 13

This proposed standard defines an Alert signal that is used by an eSPI slave to request service from the master. In a performance-oriented design or a design with only one eSPI slave, each eSPI slave will have its Alert pin connected to an Alert pin on the eSPI master that is dedicated to each slave, allowing the eSPI master to grant low-latency service because the eSPI master will know which eSPI slave needs service and will not need to poll all of the slaves to determine which device needs service. In a budget design with more than one eSPI slave, all of the Alert pins of the slaves are connected to one Alert pin on the eSPI master in a wired-OR connection, which will require the master to poll all the slaves to determine which ones need service when the Alert signal is pulled low by one or more peripherals that need service. Only after all of the devices are serviced will the Alert signal be pulled high due to none of the eSPI slaves needing service and therefore pulling the Alert signal low. 13

This proposed standard allows designers to use 1-bit, 2-bit, or 4-bit communications at speeds from 20 to 66 MHz to further allow designers to trade off performance and cost. 13

All communications that were out-of-band of the LPC bus like general-purpose input/output GPIO and System Management Bus SMBus are tunneled through the eSPI bus via virtual wire cycles and out-of-band message cycles respectively in order to remove those pins from motherboard designs using eSPI. 13

This proposed standard will support standard memory cycles with lengths of 1 byte to 4 kibibytes of data, short memory cycles with lengths of 1, 2, or 4 bytes that have much less overhead compared to standard memory cycles, and I/O cycles with lengths of 1, 2, or 4 bytes of data which are low overhead as well. This significantly reduces overhead compared to the LPC bus, whose throughput is nearly totally dominated by overhead. The standard memory cycle allows a length of anywhere from 1 byte to 4 kibibytes in order to allow its overhead to be amortized over a large transaction. eSPI slaves are allowed to initiate bus master versions of all of the memory cycles. Bus master I/O cycles, which were introduced by the LPC bus specification, and ISA-style DMA including the 32-bit variant introduced by the LPC bus specification, are not present in eSPI. Therefore, bus master memory cycles are the only allowed DMA in this standard. 13

eSPI slaves are allowed to use the eSPI master as a proxy to perform flash operations on a standard SPI flash memory slave on behalf of the requesting eSPI slave. 13

64-bit memory addressing is also added, but is only permitted when there is no equivalent 32-bit address. 13

Secure Digital - SD, SDHC, SDXC cards.

Universal Metering Interface UMI

Note: on chips where a same shift register is used for both input and output typical hardware, if one of the devices does not update in time the byte to be sent especially the slave which has no control over the clock, the last data received will be sent back like an echo. This may be taken into consideration when designing a new communication protocol over SPI, which has no flow control.

SPI Block Guide V03.06, Freescale Semiconductor

Maxim-IC application note 3947: Daisy-Chaining SPI Devices

AVR910 - In-system programming

SPI Adapter with support of custom serial protocols, Byte Paradigm.

Queued Serial Module Reference Manual, Freescale Semiconductor

Such as with the MultiChannel Serial Port Interface, or McSPI, used in Texas Instruments OMAP chips.

Such as the SPI controller on Atmel AT91 chips like the at91sam9G20, which is much simpler than TI s McSPI.

MICROWIRE Serial Interface National Semiconductor Application Note AN-452

MICROWIRE/PLUS Serial Interface for COP800 Family National Semiconductor Application Note AN-579

Serial Peripheral Interface SPI Flash Memory Backgrounder, Spansion

a b c d e f g h https://downloadcenter.intel.com/Detail_Desc.aspx.lang eng changeLang true DwnldID 22112

Wikimedia Commons has media related to Serial Peripheral Interface.

Intel eSPI Enhanced Serial Peripheral Interface

Introduction to SPI and I2C protocols

SPI Introduction with helpful diagrams

Serial Flash Lots of good information on SPI part manufacturers and models.

SPI - PICmicro Serial Peripheral Interface, Microchip company tutorial on SPI.

OpenCores Open Source implementation of SPI written in Verilog; simpler MC68HC11 version

SPI flash memory controller, HDL Design House

Retrieved from Serial_Peripheral_Interface_Bus oldid 630671646

Categories: Computer busesSerial buses.

Serial Peripheral Interface – SPI Basics. Hey all. It s time to continue with our tutorials on serial communication. Till now, we have covered the following.

Intro: The Serial - MIDI converter SM Serial MIDI Converter is a software solution to get your computer s serial port or virtual serial port over USB talking.

This library allows you to communicate with SPI devices, with the Arduino as the master device. A Brief Introduction to the Serial Peripheral Interface SPI.

In telecommunication and computer science, serial communication is the process of sending data one bit at a time, sequentially, over a communication channel or.

The Serial Peripheral Interface SPI bus is a synchronous serial communication interface specification used for short distance communication, primarily in embedded.

This is a small ATtiny84 based device to program I2C and SPI EEPROM chips over a serial port. As usual all code and schematics are available in GitHub. Background.

Introduction. Serial Peripheral Interface SPI is an interface bus commonly used to send data between microcontrollers and small peripherals such as shift registers.

A serial peripheral interface SPI is an electronic interface that provides a serial exchange of data between two devices, one called a master and the other called a.